- ACRYSTEX MS RESIN

- AMILAN™ PA

- BIFFA r-HDPE

- BIFFA r-PP COMPOUND

- CELANEX® PBT

- CELANYL® PA

- CLEARFLEX LLDPE

- CRASTIN

- DELRIN

- DIAKON PMMA

- DISTRUPOL-PRECW

- DRYFLEX CIRCULAR

- DRYFLEX TPE

- ECOMID® PA

- EGYEUROPTENE

- ELASTOLLAN TPU

- ELTEX MED

- ELTEX P POLYPROPYLENE

- ELVAKON PMMA

- ENTHOVEN RECYCLED PPC

- ERACLENE HDPE

- EVICOM PVC COMPOUNDS

- FLEXIRENE LLDPE

- FRIANYL® PA

- GREENFLEX EVA

- HY-VIN PVC COMPOUNDS

- HYTREL

- INEOS EBA

- INEOS EMAA

- INEOS LDPE

- INEOS LLDPE

- INEOS PP

- INEOS mLLDPE

- IPETHENE LDPE

- KIBILAC ASA

- KIBISAN SAN

- KIBITON Q-RESIN

- KIBITON TPE

- LG ABS

- LG ASA

- LG LUPOX PC/PBT

- LG LUPOY PC

- LG LUPOY PC/ABS

- LG LUPOY PC/ASA

- LG LUSEP PPS

- LG SAN

- MEDALIST TPE

- MEDIPRENE TPE

- MINLON PA

- MONPRENE TPE

- PEARLENE

- PHARMALENE PE & EVA

- PINNACLE HPP

- PINNACLE ICPP

- PINNACLE RCPP

- POLYCHIM PP

- POLYLAC ABS

- POLYREX PS

- PURGEX CLEANING COMPOUND

- PVOH (Polyvinyl Alcohol)

- RECYCL-IN

- RIBLENE LDPE

- RIGIDEX HDPE

- RIGIDEX MDPE

- RYNITE PET

- SARLINK TPV AND TPE

- THERMOFIL REINFORCED PP COMPOUNDS

- TORAYCON PBT

- TORELINA PPS

- TOYOLAC ABS

- TOYOLAC MABS

- TRIFILON BIOLITE

- TRIFILON REVO

- TRIFILON SWITCH

- TUFCOAT PMMA

- WELLS PLASTIC ANTISTATICS

- WELLS PLASTICS ANTIBLOCKS

- WELLS PLASTICS ANTIMICROBIALS

- WELLS PLASTICS ANTIOXIDANTS

- WELLS PLASTICS BLOWING AGENTS

- WELLS PLASTICS FLAME RETARDANT MASTERBATCHES

- WELLS PLASTICS FRAGRANCES

- WELLS PLASTICS OXO BIODEGRADABLES

- WELLS PLASTICS PROCESSING AIDS

- WELLS PLASTICS PURGE AND CLEANING COMPOUNDS

- WELLS PLASTICS SLIP AGENTS

- WELLS PLASTICS UV STABILISERS

- WONDERLITE PC

- WONDERLOY PC/ABS

- ZYTEL PLUS

- ZYTEL HTN

- ZYTEL LCPA

- ZYTEL PA

- ZYTEL RS

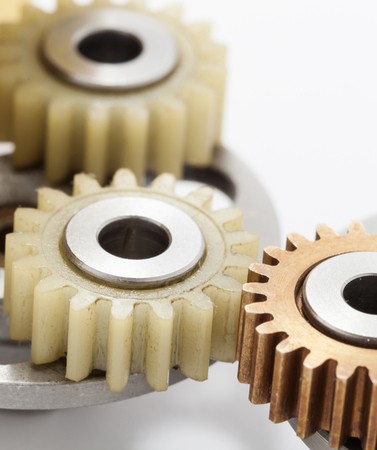

Metal Replacement

Delrin® POM acetal homopolymer bridges the gap between metal and plastics with a unique combination of mechanical properties. The advantageous properties of Delrin® make it ideal for applications such as gears, clips, fasteners, bearings, conveyor belts, switches, handles, screws, springs, valves and much more, across an extensive variety of industries.

Spotlight on Delrin®:

- High tensile strength, stiffness and creep resistance

- Significantly higher impact resistance

- Dimensional stability due to low moisture pickup

- Low friction

- Service temperatures from below -50°C to +90°C (intermittent to 120°C)

- Low emission grades

- Lower molecular weight*

*Lower molecular weight also results in a significant improvement in melt flow rate (MFR) and mouldability, allowing for thinner and lighter part design, shorter moulding cycles and the potential for cost reductions.

Invented in 1960, Delrin® is widely used in many applications around the world today, including in the automotive, industrial, electronic, consumer goods and medical industries. It is a highly-crystalline engineering thermoplastic which is often specified for high load mechanical applications because of its stiffness, toughness and strength, without the need for reinforcement.

© 2023 Distrupol. All rights reserved.