- ACRYSTEX MS RESIN

- AGON®

- AMILAN™ PA

- BIFFA r-HDPE

- BIFFA r-PP COMPOUND

- CELANEX® PBT

- CELANYL® PA

- CLEARFLEX LLDPE

- CRASTIN

- DIAKON PMMA

- DISTRUPOL-PRECW

- DRYFLEX® CIRCULAR

- DRYFLEX® GREEN

- DRYFLEX® TPE

- DUTRAL®

- ECOMID® PA

- EGYEUROPTENE

- ELASTOLLAN TPU

- ELTEX MED

- ELTEX P POLYPROPYLENE

- ELVAKON PMMA

- ENTHOVEN RECYCLED PPC

- ERACLENE HDPE

- EUROPRENE®

- EVICOM PVC COMPOUNDS

- FLEXIRENE LLDPE

- FRIANYL® PA

- GREENFLEX EVA

- HY-VIN PVC COMPOUNDS

- HYTREL

- INEOS EBA

- INEOS EMAA

- INEOS LDPE

- INEOS LLDPE

- INEOS PP

- INEOS mLLDPE

- IPETHENE LDPE

- KEPITAL™ POM

- KIBILAC ASA

- KIBISAN SAN

- KIBITON Q-RESIN

- KIBITON TPE

- LG ABS

- LG ASA

- LG LUPOX PC/PBT

- LG LUPOY PC

- LG LUPOY PC/ABS

- LG LUPOY PC/ASA

- LG LUSEP PPS

- LG SAN

- MEDALIST TPE

- MEDIPRENE TPE

- MINLON PA

- MONPRENE TPE

- PEARLENE

- PHARMALENE PE & EVA

- PINNACLE HPP

- PINNACLE ICPP

- PINNACLE RCPP

- POLYCHIM PP

- POLYLAC ABS

- POLYREX PS

- PURGEX CLEANING COMPOUND

- PVOH (Polyvinyl Alcohol)

- RECYCL-IN

- RIBLENE LDPE

- RIGIDEX HDPE

- RIGIDEX MDPE

- RYNITE PET

- SARLINK TPV AND TPE

- THERMOFIL REINFORCED PP COMPOUNDS

- TORAYCON PBT

- TORELINA PPS

- TOYOLAC ABS

- TOYOLAC MABS

- TRIFILON BIOLITE

- TRIFILON REVO

- TRIFILON SWITCH

- WELLS PLASTIC ANTISTATICS

- WELLS PLASTICS ANTIBLOCKS

- WELLS PLASTICS ANTIMICROBIALS

- WELLS PLASTICS ANTIOXIDANTS

- WELLS PLASTICS BLOWING AGENTS

- WELLS PLASTICS FLAME RETARDANT MASTERBATCHES

- WELLS PLASTICS FRAGRANCES

- WELLS PLASTICS OXO BIODEGRADABLES

- WELLS PLASTICS PROCESSING AIDS

- WELLS PLASTICS PURGE AND CLEANING COMPOUNDS

- WELLS PLASTICS SLIP AGENTS

- WELLS PLASTICS UV STABILISERS

- WONDERLITE PC

- WONDERLOY PC/ABS

- ZYTEL PLUS

- ZYTEL HTN

- ZYTEL LCPA

- ZYTEL PA

- ZYTEL RS

DRYFLEX® TPE

The Dryflex® portfolio is an extremely diverse and sophisticated family of technical SBS and SEBS compounds which are engineered to meet the most demanding challenges in a vast range of industrial applications.

Dryflex® is versatile and easily processed by a number of different methods, with a range of hardnesses from 0 Shore A to 65 Shore D. It is colourable or transparent making it the material of choice for a diverse range of applications. With a wide service temperature range, it has improved chemical resistance and fast cycle times whilst being fully recyclable and reprocessable.

Dryflex® 2K

Dryflex® 2K is a range of adhesion TPEs that facilitate the production of applications with soft-touch qualities or integrated seal components. Since the materials are bonded together at the production stage, no separate primer or adhesive is needed, making the process faster and more cost-effective.

Dryflex® 2K grades form excellent bonds onto PP, PE, PA, ABS, PC, PS, PMMA, ASA, SAN and their blends.

The portfolio consists of: A1 series - adhesion to Polyamide; A01 series - adhesion to Polyamide using lower processing temperatures; A2 series - adhesion to ABS, PC, PC/ABS, PMMA, SAN, ASA & blends; and A3 series - adhesion to Polystyrene

Applications include two component grips & handles, wheels, power tools, automotive components (e.g. sealing, gaskets, dampening systems), and packaging.

Dryflex® AM

Dryflex® AM is a range of TPE materials specifically designed to address the requirements for automotive mats. Applications for Dryflex® AM materials include floor mats, trunk liners, coin mats, fascia mats and trim.

For automotive floor mats, the materials need to have high scratch and abrasion resistance. It is also critical that the material is non-slip, even when wet. The material structure of Dryflex® AM compounds produces the surface finish and high friction required.

Dryflex® Antimicrobial

Dryflex® Antimicrobial TPE can help to prevent the spread of harmful bacteria and encourage the safe protection of everyday products in hospitals, public places or at home.

Dryflex® Antimicrobial TPEs attack micro-organisms at source, helping prevent problems before they occur. Samples have been independently tested and proven to kill >99.9% of gram positive and negative bacteria when tested by the recognised ISO 22196 test method. They are effective against MRSA, E-Coli, Pseudomonas Aeroginosa and Salmonella and many other harmful bacteria.

Applications include consumer goods, areas with a heavy footfall such as schools, shopping centres & gyms, sports equipment, healthcare and clinical environments, public transport and packaging.

Dryflex® C

Dryflex® C is a range of conductive TPEs, suitable for applications such as grips, handles and elements for electrical tools and appliances.

The product range consist of the C1 series and C3 series, which provide a wealth of properties in both natural (colourable) and black, with surface resistivity down to 108Ω and 103Ω respectively.

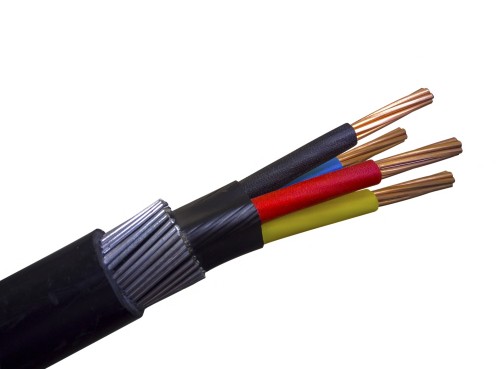

Dryflex® Cable

The Dryflex® Cable compounds are designed to meet the highest levels of durability, performance and human safety in applications such as cable sheathing, bedding and insulation.

The range includes grades based on different polymer chemistries, including EVA, TPE and TPV technologies. This brings one of the widest ranges of properties and customisation possibilities to the market and gives cable manufacturers the flexibility to select the best solution for their application.

The Dryflex® Cable range includes Low Smoke Halogen Free (LSHF) or Low Smoke Zero Halogen (LSZH) flame retardant compounds. They are designed to offer enhanced flame-retardant properties with low smoke and toxicity. The compounds are RoHS, SVHC and REACH compliant and halogen-free according to IEC 60754 Part 1/2.

Dryflex® CS

Dryflex® CS is a range of SEBS compounds that has been engineered to deliver optimised compression set performance. Compression set is the measure of permanent deformation remaining when an applied force is removed, ideal applications for this material include gaskets, flexible connectors, food packaging, valves and seals.

The raw materials used to manufacture Dryflex® CS compounds are compliant with major food contact regulations and the compounds also offer excellent organoleptic performance.

Dryflex® DW

Dryflex® DW is a special range of TPEs for applications that come into contact – directly or indirectly – with water. In order to maintain the integrity of water as it transitions through the water systems, Dryflex® DW grades are designed to meet the requirements for the Germany drinking water regulations KTW and are suitable for both domestical and commercial applications such as plumbing seals, pipe fittings and shower-heads.

Dryflex® Extrusion

Dryflex® Extrusion is a range specifically designed for extruded profile applications such as window and door sealing applications that require efficient processing, high performance, and the added bonus of recyclability. The range includes translucent, foamable, rigid and semi-rigid compounds and colour and co-extrusion have further enhanced the design possibilities with this material.

Dryflex® Flam

Dryflex® Flam grades are halogen-free flame retardant TPEs that are designed to meet the most demanding applications where resistance to ignition and burning are important features.

The flame-retardant grades are used in cable grommets, plug tops, electrical insulation, cords and connectors, railroad, cavity wall sockets as well as miscellaneous gasket profiles.

The Flam 600 series fulfils the specification of UL 94 V0 with 3mm wall thickness and the Flam 700 series fulfils the specification of UL 94 V0 with 1.5mm wall thickness. Both series are flame retardant, halogen free, and easy processing by injection moulding and extrusion.

Dryflex® HiF

Dryflex® HiF is a novel technology polymer portfolio which are very high melt-flow designed specifically for automotive interiors. This portfolio was originally designed for injection moulded panels and skins, but could be used in application areas where very high flowing materials are needed.

Dryflex® Interior

Dryflex® PS

Dryflex® PS is designed for seals and pipe joints used in wastewater applications. The Dryflex® PS grades meet the requirements of EN 681-2:2000, the European Standard EN 681-2, Type WT.

Dryflex® SE

Dryflex® SE is that core portfolio of Dryflex® which consists of series’ of unfilled, semi-filled and filled grades. From 30-90 Shore A hardnesses, with high flexibility, good adhesion to PP & PE, easy processing and good mechanical properties, there are a versatile range of formulations to fulfil different properties and application requirements

Applications include soft touch grips and handles, sealing and closures for packaging, sports equipment, toys and infant care, soft-touch areas for packaging, storage box sealings, tools and hardware, and automotive components.

Dryflex® T

Dryflex® T is a family of fully transparent grades offering hardnesses from 30 to 90 Shore A. Grades with compliance to major food regulations are available. They are microwave, dishwasher and freezer friendly and offer excellent adhesion to PP.

Applications include high value packaging, personal care items, sporting goods and goggles, grips and handles, and food containers.

Dryflex® Touch

Dryflex® Touch is a range of TPEs designed to give a superior soft and silky touch feeling to users. Formulated with durability and product aesthetics in mind, the grades offer vibrant colour options, UV and scratch resistance.

Applications include wearable technology, consumer electronics, smartphone and tablet protective cases, wrist straps, grips, cosmetics and packaging.

Dryflex® TPU

Dryflex® TPU compoundsare ideal for use in the footwear, industrial and automotive industries.

Foamable for light weight Dryflex® TPU compounds are particularly interesting, they can be used in the form of foams of up to 0.45 g/cm3 in new areas within the footwear industry, as well as in injection moulding, or extrusion. The foaming types are available in shore A hardness of approx 52 to 70.

Dryflex® TPV

Dryflex® TPV compounds are high performance materials designed for demanding applications where improved durability, heat or fluid resistance are required.

Dryflex® TPV compounds combine the processing ease, efficiency and recyclability of a thermoplastic with the improved flexibility, low compression set and resistance to aggressive fluids of a vulcanised rubber.

Applications include automotive (interior, exterior and under-bonnet), electronics and appliances, white goods, consumer goods, and building and construction.

Dryflex® WS

Dryflex® WS are a range of TPEs which contain hydrophilic particles. They swell at a controlled rate and percentage when immersed in water.

Dryflex® WS and WS+ materials are used in applications to form a positive seal and prevent the ingress or exit of water. They are an ideal choice for water stop applications where the profiles may be coiled or need to be fitted around complex structures.

Applications include waterstops, water treatment plants, tunnels, drains & sewers, water tanks, and seals.

Want to explore more sustainable TPE solutions? Discover Dryflex® Circular and Dryflex® Green today.

Useful information

Select a resource from the drop down to find out more:

- Dryflex_TPV.pdf

- Dryflex_for_Automotive_Interiors.pdf

- Dryflex_for_Wire_and_Cable_Applications.pdf

- Dryflex_Cable.pdf

- Dryflex_Flam.pdf

- Dryflex_SE_for_Injection_Moulding.pdf

- Dryflex_DW.pdf

- Dryflex_Antimicrobial.pdf

- Dryflex_PS.pdf

- Dryflex_CS_with_Optimised_Compression.pdf

- Hexpol-s_Big_Little_Book_of_Cable.pdf

- Dryflex_for_Impact_Modification.pdf

- Dryflex_Interior.pdf

- Dryflex_AM.pdf

- Dryflex_WS.pdf

Looking for datasheets & UL yellow cards?

Select the grade from the below list.

Technical questions?

Click here to complete a form and a member of the technical team will be in touch shortly.

Need a quote?

Click here to complete a short form and a team member will be in touch shortly.

© 2025 Distrupol. All rights reserved.