Product search

Trade name

- ACRYSTEX MS RESIN

- AGON®

- AMILAN™ PA

- BIFFA r-HDPE

- BIFFA r-PP COMPOUND

- CELANEX® PBT

- CELANYL® PA

- CLEARFLEX LLDPE

- CRASTIN

- DIAKON PMMA

- DISTRUPOL-PRECW

- DRYFLEX® CIRCULAR

- DRYFLEX® GREEN

- DRYFLEX® TPE

- DUTRAL®

- ECOMID® PA

- EGYEUROPTENE

- ELASTOLLAN TPU

- ELTEX MED

- ELTEX P POLYPROPYLENE

- ELVAKON PMMA

- ENTHOVEN RECYCLED PPC

- ERACLENE HDPE

- EUROPRENE®

- EVICOM PVC COMPOUNDS

- FLEXIRENE LLDPE

- FRIANYL® PA

- GREENFLEX EVA

- HY-VIN PVC COMPOUNDS

- HYTREL

- INEOS EBA

- INEOS EMAA

- INEOS LDPE

- INEOS LLDPE

- INEOS PP

- INEOS mLLDPE

- IPETHENE LDPE

- KEPITAL™ POM

- KIBILAC ASA

- KIBISAN SAN

- KIBITON Q-RESIN

- KIBITON TPE

- LG ABS

- LG ASA

- LG LUPOX PC/PBT

- LG LUPOY PC

- LG LUPOY PC/ABS

- LG LUPOY PC/ASA

- LG LUSEP PPS

- LG SAN

- MEDALIST TPE

- MEDIPRENE TPE

- MINLON PA

- MONPRENE TPE

- PEARLENE

- PHARMALENE PE & EVA

- PINNACLE HPP

- PINNACLE ICPP

- PINNACLE RCPP

- POLYCHIM PP

- POLYLAC ABS

- POLYREX PS

- PURGEX CLEANING COMPOUND

- PVOH (Polyvinyl Alcohol)

- RECYCL-IN

- RIBLENE LDPE

- RIGIDEX HDPE

- RIGIDEX MDPE

- RYNITE PET

- SARLINK TPV AND TPE

- THERMOFIL REINFORCED PP COMPOUNDS

- TORAYCON PBT

- TORELINA PPS

- TOYOLAC ABS

- TOYOLAC MABS

- TRIFILON BIOLITE

- TRIFILON REVO

- TRIFILON SWITCH

- WELLS PLASTIC ANTISTATICS

- WELLS PLASTICS ANTIBLOCKS

- WELLS PLASTICS ANTIMICROBIALS

- WELLS PLASTICS ANTIOXIDANTS

- WELLS PLASTICS BLOWING AGENTS

- WELLS PLASTICS FLAME RETARDANT MASTERBATCHES

- WELLS PLASTICS FRAGRANCES

- WELLS PLASTICS OXO BIODEGRADABLES

- WELLS PLASTICS PROCESSING AIDS

- WELLS PLASTICS PURGE AND CLEANING COMPOUNDS

- WELLS PLASTICS SLIP AGENTS

- WELLS PLASTICS UV STABILISERS

- WONDERLITE PC

- WONDERLOY PC/ABS

- ZYTEL PLUS

- ZYTEL HTN

- ZYTEL LCPA

- ZYTEL PA

- ZYTEL RS

Website search

Electrolytic Corrosion Preventative Technology

Advances in EV technology increasingly requires materials that can handle contact with various fluids, and low to high voltage loads in different conditions such as temperature and humidity.

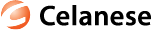

EV drivetrain safety calls for increased durability of components and improved electrical properties. Electrical components - such as connectors, switches, relays, busbars and sensors - can malfunction or short circuit when voltage is applied. Malfunctions often occur because of three factors: surface moisture, elevated temperature, and traces of halide ions such as chlorine, bromine, or iodine that can lead to electrolytic corrosion. The Zytel® EF portfolio overcomes these performance challenges.

Zytel® Electronic Friendly uses organic stabilisers as opposed to the metal halides that are the industry standard for polyamides. When exposed to heat and moisture, the molecular bond between the metal and halide will break down, and ions will migrate towards the electrical metal inserts and form platelets (dendrites). These can potentially create a conductive path, and if the positive and negative connectors make a circuit, the electronics will short and fail.

Automotive manufacturers rely on the Zytel® EF portfolio to drive the innovation of plastic solutions that perform under the intensity of low and high voltage applications with:

- Organic heat-stabilised materials that extend component lifetime by preventing electrolytic corrosion

- Materials based on different chemistry to address specific temperature and chemical resistance

- Materials with different glass fibre levels

- Laser-markable formulations that allow for part identification through QR and DMC codes

- Materials designed for high flow and laser transparency for laser welding to boost productivity and improve ease of assembly

Spotlight on Zytel® Electronic Friendly (EF):

- Features organic stabilisers rather than metal

- Insulating, electrical resistance

- Heat resistance

- Chemical resistance

- Strength & stiffness

- Dimensional stability

- Easy to process

- Versatility

- Fatigue resistance

© 2025 Distrupol. All rights reserved.