- ACRYSTEX MS RESIN

- AGON®

- AMILAN™ PA

- BIFFA r-HDPE

- BIFFA r-PP COMPOUND

- CELANEX® PBT

- CELANYL® PA

- CLEARFLEX LLDPE

- CRASTIN

- DIAKON PMMA

- DISTRUPOL-PRECW

- DRYFLEX® CIRCULAR

- DRYFLEX® GREEN

- DRYFLEX® TPE

- DUTRAL®

- ECOMID® PA

- EGYEUROPTENE

- ELASTOLLAN TPU

- ELTEX MED

- ELTEX P POLYPROPYLENE

- ELVAKON PMMA

- ENTHOVEN RECYCLED PPC

- ERACLENE HDPE

- EUROPRENE®

- EVICOM PVC COMPOUNDS

- FLEXIRENE LLDPE

- FRIANYL® PA

- GREENFLEX EVA

- HY-VIN PVC COMPOUNDS

- HYTREL

- INEOS EBA

- INEOS EMAA

- INEOS LDPE

- INEOS LLDPE

- INEOS PP

- INEOS mLLDPE

- IPETHENE LDPE

- KIBILAC ASA

- KIBISAN SAN

- KIBITON Q-RESIN

- KIBITON TPE

- LG ABS

- LG ASA

- LG LUPOX PC/PBT

- LG LUPOY PC

- LG LUPOY PC/ABS

- LG LUPOY PC/ASA

- LG LUSEP PPS

- LG SAN

- MEDALIST TPE

- MEDIPRENE TPE

- MINLON PA

- MONPRENE TPE

- PEARLENE

- PHARMALENE PE & EVA

- PINNACLE HPP

- PINNACLE ICPP

- PINNACLE RCPP

- POLYCHIM PP

- POLYLAC ABS

- POLYREX PS

- PURGEX CLEANING COMPOUND

- PVOH (Polyvinyl Alcohol)

- RECYCL-IN

- RIBLENE LDPE

- RIGIDEX HDPE

- RIGIDEX MDPE

- RYNITE PET

- SARLINK TPV AND TPE

- THERMOFIL REINFORCED PP COMPOUNDS

- TORAYCON PBT

- TORELINA PPS

- TOYOLAC ABS

- TOYOLAC MABS

- TRIFILON BIOLITE

- TRIFILON REVO

- TRIFILON SWITCH

- WELLS PLASTIC ANTISTATICS

- WELLS PLASTICS ANTIBLOCKS

- WELLS PLASTICS ANTIMICROBIALS

- WELLS PLASTICS ANTIOXIDANTS

- WELLS PLASTICS BLOWING AGENTS

- WELLS PLASTICS FLAME RETARDANT MASTERBATCHES

- WELLS PLASTICS FRAGRANCES

- WELLS PLASTICS OXO BIODEGRADABLES

- WELLS PLASTICS PROCESSING AIDS

- WELLS PLASTICS PURGE AND CLEANING COMPOUNDS

- WELLS PLASTICS SLIP AGENTS

- WELLS PLASTICS UV STABILISERS

- WONDERLITE PC

- WONDERLOY PC/ABS

- ZYTEL PLUS

- ZYTEL HTN

- ZYTEL LCPA

- ZYTEL PA

- ZYTEL RS

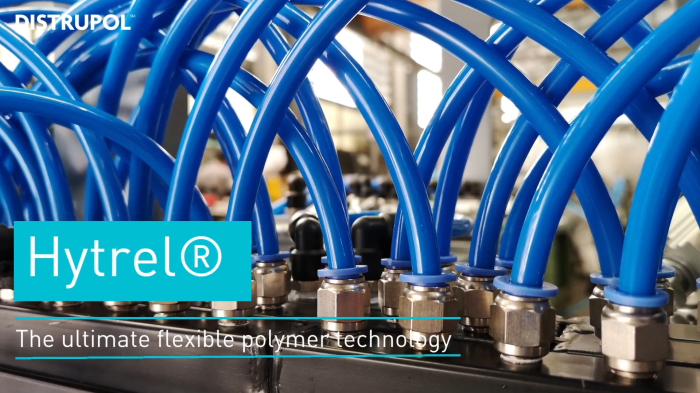

HYTREL

Flexible Polyester Elastomer Technology

Hytrel® is a TPC-ET thermoplastic polyester elastomer based on block copolymer technology

By leveraging the flexibility of rubber and the strength and processability of plastic, Hytrel® is a versatile and high-performance polymer which facilitates the design and manufacture of a wide variety of products.

With Hytrel®, it is possible to design and manufacture unique products combining many of the best features of high-performance elastomers and flexible plastic materials, whilst maintaining durability, chemical resistance and wide temperature range functionality.

The Hytrel® portfolio

The Hytrel® TPC-ET portfolio leads the way in flexible, plasticiser-free polymer solutions across a wide range of industries including the medical, automotive, consumer and industrial markets.

Hytrel® available in a full range of Shore D hardnesses and is categorised into six main groups:

- Hytrel® G – general purpose grades of TPC-ET. These grades offer the best balance of properties and cost.

- Hytrel® - high performance grades of TPE-ET. These grades provide an extra measure of strength or serviceability in the most demanding applications and can be used in light-coloured parts.

- Hytrel® HTR – specialty grades of TPC-ET. These grades include grades with enhanced properties or processing characteristics for specific applications

- Hytrel® PC / SC – TPE-ET certified for healthcare / medical applications.

- Hytrel® Concentrates – there are various additive-containing concentrates which can be blended with other Hytrel® resins to enhance specific properties, for example UV light stabilisers, flame retardant concentrates and heat stabilisers.

- Hytrel® ECO B - delivering all of the benefits of Hytrel®, yet it contains up to 60 percent renewably sourced materials from biomass.

Economical processing with Hytrel®

Hytrel® can be processed by injection moulding, blow moulding, rotational moulding, extrusion, and sheet, blown or cast film. The design and manufacturing versatility of Hytrel® often results in lighter weight and lower cost parts versus rubbers and other elastomers.

This makes Hytrel® the economical and sustainable choice.

Hytrel® TPC-ET's unique properties

Hytrel® offers a unique combination of mechanical, physical, and chemical properties that qualifies it for the most demanding applications.

Ideal applications for Hytrel®

Hytrel® is well known in the marketplace for providing designers with flexible design and manufacturing solutions. With an extensive variety of grades and concentrates available, Hytrel® leads the way for plasticiser-free TPC-ET solutions.

Our dedicated Hytrel® industry pages go into detail about the attributes of Hytrel® that make it ideal for particular applications.

Useful information

Select a resource from the drop down to find out more:

Looking for datasheets & UL yellow cards?

Select the grade from the below list.

© 2025 Distrupol. All rights reserved.